Welcome to our comprehensive guide on silicone tubing, a crucial component in the pharmaceutical industry. Silicone tubing, known for its flexibility, durability, and chemical inertness, plays a pivotal role in various pharmaceutical processes. In this guide, we will discuss why silicone tubing is the preferred choice for pharmaceutical applications, covering its benefits, applications, and maintenance. To discover more about our high-purity silicone tubing and how it can enhance your pharmaceutical operations, contact Fluid Biosolutions today.

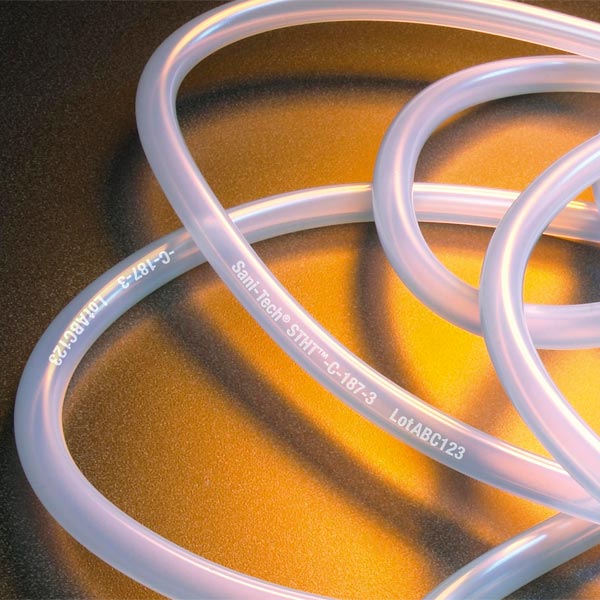

Silicone tubing is a cornerstone in the pharmaceutical industry, prized for its exceptional properties. It stands out for its remarkable flexibility, making it ideal for various fluid transfer applications. Additionally, its inert nature ensures that it does not react with medications or biological samples, preserving their purity. The tubing’s ability to withstand a wide range of temperatures, from extreme cold to intense heat, without degradation, is crucial for maintaining the integrity of sensitive pharmaceutical products. These features make silicone tubing indispensable in pharmaceutical manufacturing and research labs.

Benefits of Using Silicone Tubing

One of the key benefits of silicone tubing in pharmaceutical applications is its non-reactivity. This property is crucial as it ensures that the tubing does not leach chemicals into the products or react with the substances it transports. This is particularly important in the pharmaceutical industry, where product purity is paramount. Silicone tubing is also known for its excellent thermal stability. It can operate in a wide temperature range without losing its flexibility or structural integrity, making it ideal for processes involving heat sterilisation.

Another advantage is its longevity and durability. Silicone tubing can withstand repeated use and sterilisation processes without degrading, making it a cost-effective and reliable choice for long-term use. Furthermore, its translucency allows for easy monitoring of fluid flow, which is essential in many pharmaceutical operations.To explore our range of silicone tubing, please visit our silicone tubing page here.

Applications in the Pharmaceutical Industry

Silicone tubing is extensively used in various pharmaceutical operations. Its application ranges from being a part of peristaltic pumps, which are essential for moving fluids through processes without contamination, to its use in drug delivery systems where precision and purity are critical. In laboratories, silicone tubing is used in applications requiring high levels of cleanliness and non-toxicity, such as in the handling of sensitive biological samples. Its versatility also extends to being used in manufacturing processes, where it aids in the safe transfer of raw materials and finished products. Please see below examples of specific applications of silicone tubing in the pharmaceutical industry:

Selecting the Right Silicone Tubing

Choosing the appropriate silicone tubing for pharmaceutical applications involves several key considerations:

Maintenance and Care Tips for Silicone Tubing

Proper maintenance is crucial for maximising the lifespan and effectiveness of silicone tubing in pharmaceutical applications:

Innovations and Future Trends in Silicone Tubing Technology

The pharmaceutical industry is at the forefront of innovation, and this extends to the development of silicone tubing technologies. There is ongoing research into new silicone compounds that promise enhanced performance characteristics, especially in terms of durability and chemical compatibility. Moreover, customisation is becoming increasingly important, with tubing solutions being tailored to meet the unique requirements of specific pharmaceutical applications.

Looking ahead, the integration of smart technology in silicone tubing is a potential trend. This could involve embedding smart sensors within the tubing to monitor fluid properties in real-time, offering unprecedented levels of control and safety. Additionally, in response to global environmental concerns, there is a growing focus on developing more eco-friendly silicone tubing options. These advancements not only promise to improve the functionality of silicone tubing but also align with the sustainability goals of the pharmaceutical industry.

Case Studies and Real-World Examples

To illustrate the impact of silicone tubing in the pharmaceutical industry, let’s explore a few case studies:

Each of these examples demonstrates the versatility and effectiveness of silicone tubing in real-world pharmaceutical applications.

In conclusion, silicone tubing stands as a pivotal element in the pharmaceutical industry, known for its versatility, safety, and efficiency. From enhancing drug delivery systems to improving laboratory research, its impact is widespread and crucial. As we have seen, advancements in this field continue to push the boundaries, promising even more innovative applications in the future. For those in the pharmaceutical sector, understanding and utilising the benefits of high-quality silicone tubing is not just an option, but a necessity for continued success and innovation.

Remember, for all your silicone tubing needs, explore our extensive range at Fluid BioSolutions’ High-Purity Tubing and Hoses.

To find out more about how we can create a customized solution for your needs, contact our friendly team here.

In the realm of scientific discovery and industrial efficiency, the centrifuge stands as a pivotal tool, elegantly separating components with its rotational prowess. At Fluid BioSolutions, we understand the critical role centrifuges play in diverse sectors. This deep dive into centrifuge mechanics aims to enlighten our readers on the intricacies of this essential equipment, from its historical origins to the latest technological advancements.

Discover our range of centrifuges, each embodying the pinnacle of design and functionality.

At its core, the centrifuge operates on a fundamental principle: centrifugal force. This force, a cornerstone in the functionality of every centrifuge, emerges when an object rotates around a central point, moving away due to inertia. In the context of a centrifuge, this translates to the rapid spinning of samples, which leads to the effective separation of components based on their density.

As a centrifuge spins, denser particles move outward, settling against the outer walls of the bowl, while lighter components remain closer to the centre. This elegant yet powerful mechanism enables precise separation in myriad applications, from medical diagnostics to environmental analysis.

The centrifuge’s versatility lies in its ability to be tailored for specific tasks. Variations in speed, rotor type, and duration of spin allow for the meticulous separation of different substances, highlighting the centrifuge’s indispensable role in scientific and industrial fields.

Centrifuges come in various forms, each designed to cater to specific requirements. The most common types include:

Each type of centrifuge, while based on the same basic principle of centrifugation, offers unique features to suit different applications. This diversity not only showcases the versatility of centrifuges but also underlines their indispensability in various scientific fields.

Understanding the components of a centrifuge is key to appreciating its functionality and versatility. The primary parts include:

These components work in unison, each playing a pivotal role in the centrifuge’s operation. This intricate cooperation underscores the centrifuge’s significance in various scientific and industrial applications.

The magic of a centrifuge lies in its ability to separate components through rotational force. This process begins as the centrifuge’s rotor spins at high speeds, creating a force that pushes heavier particles outward. In a mixture, this means that denser substances are flung to the outer edges, while lighter substances remain closer to the centre.

The efficiency of separation depends on several factors: the speed of rotation, the size and density of the particles, and the duration of the spin. By manipulating these variables, a centrifuge can be fine-tuned to separate a wide range of substances, from blood components in medical laboratories to sediments in geological studies.

This principle of rotational separation is not just a cornerstone of centrifuge operation but also a testament to its versatility in various scientific applications.

Learn more about our centrifuges and their capabilities in rotational separation.

The versatility of centrifuges spans across various fields, underlining their importance in numerous applications:

Each of these applications demonstrates the centrifuge’s critical role in advancing scientific and industrial pursuits.

Proper maintenance and adherence to safety guidelines are paramount in ensuring the longevity and effective operation of centrifuges:

By following these maintenance and safety protocols, the lifespan of centrifuges can be significantly extended, ensuring their continuous role in various critical processes.

The future of centrifuge technology is marked by exciting advancements and innovative trends:

These trends not only signify the technological evolution of centrifuges but also their growing importance in a wide array of scientific and industrial applications.

In conclusion, the journey through the world of centrifuges reveals their indispensable role in modern science and industry. From their basic operating principles to the vast array of applications, centrifuges are more than just machines; they are key enablers of progress across various fields. As we have seen, ongoing advancements in centrifuge technology promise even greater efficiency and versatility in the future. Understanding the mechanics and applications of centrifuges is essential for anyone involved in scientific research, industrial processes, or any field where precise separation is crucial.

Explore the innovative world of centrifuges at Fluid BioSolutions, where we are committed to providing cutting-edge solutions for all your centrifugal needs.

For more information on our customised solutions and centrifuges, talk to our friendly team, by visiting our contact page.

As our reliance on high-performance materials continues to grow, silicone tubing is increasingly coming into the spotlight. From medical equipment to car manufacturing, this versatile material is gaining traction across diverse industries. This all-encompassing guide aims to give you a deep understanding of why silicone tubing has become indispensable and what the future holds for it.

Silicone tubing is essentially flexible tubing crafted from silicone rubber. But don’t be mistaken; this isn’t your everyday rubber. Thanks to its unique attributes, silicone has become the go-to material for an array of challenging applications. Think of it as the multi-tool of tubing: versatile, dependable, and endlessly useful.

When navigating the stringent regulations and demands of pharmaceutical manufacturing, few materials offer as comprehensive a solution as silicone tubing. Here are some of its game-changing benefits:

Crafted from high-grade, contaminant-free materials, silicone tubing is ideal for the sensitive operations within pharmaceutical production. Its lack of hazardous components like BPA ensures that it doesn’t compromise the safety of the medications it handles.

Pharmaceutical applications often demand materials that can operate efficiently across a wide temperature spectrum. Silicone tubing stands out for its capability to maintain its form and function in both high-heat and freezing conditions.

Often exposed to potent chemicals and solvents, tubing in pharmaceutical settings needs to be robust. Silicone tubing excels in this aspect by being remarkably chemical-resistant, ensuring that it doesn’t compromise the quality of the medicines it comes into contact with.

Silicone tubing can be effortlessly sterilised using a variety of methods such as autoclaving and gamma radiation. This makes it an optimal choice for pharmaceutical environments where cleanliness is non-negotiable.

Tested extensively for biocompatibility, silicone is the material of choice for medical devices and other applications that come into contact with the human body due to the many factors listed.

The pliability yet durable nature of silicone tubing makes it perfect for dynamic systems where tubing might be frequently moved or manipulated, all while retaining a stable and dependable flow rate.

Silicone tubing is not a one-size-fits-all solution. From medical-grade to food-grade, and even industrial applications, the range is extensive.

Used in an array of medical tools such as catheters and respiratory systems, silicone tubing’s inert qualities make it safe for use in medical settings.

In the realm of medication delivery, the purity and precision of silicone tubing are unmatched. It’s commonly found in IV lines and peristaltic pumps.

Silicone tubing is not just about performance; it’s a conscientious environmental choice too, being fully recyclable.

Compared to alternatives like PVC and metals, silicone tubing has a smaller environmental footprint.

From healthcare to automobiles, its applications are broad and spread across multiple industries for different purposes.

Yes, its inert and bio-friendly nature makes it medically safe.

Yes, it aligns well with sustainability goals.

It offers superior heat tolerance, purity, and flexibility.

Its purity, safety, and biocompatibility make it invaluable in medical settings.

While initial costs may be higher, its durability makes it cost-efficient over time.

The world of materials science is always evolving, but some materials, such as silicone tubing, have proven their worth time and again. With an impressive range of attributes—like flexibility, purity, durability, and heat-resilience—silicone tubing finds itself at the forefront of various industries. Whether it’s revolutionizing healthcare, making cars more efficient, or aiding in environmental sustainability, silicone tubing is a material for the future. If you’re in search of a material that not only meets but often exceeds industry standards, look no further than silicone tubing.

In the intricate world of pharmaceutical processing, the materials used play a crucial role in the efficacy and safety of drug production. Platinum cured silicone stands out as the gold standard. But what exactly is it, and why is it a standout within the industry? Let’s dive in and unravel the mystery of this phenomenal material.

Platinum cured silicone is not just another material; it’s a revolution in the world of pharmaceutical processing. Its adoption by leading companies, especially Fluid Biosolutions, underscores its unmatched attributes and potential.

Platinum cured silicone, colloquially known as the “Rolls Royce” of silicones, undergoes a unique curing process. By utilising platinum as a catalyst, this curing method allows for a high purity product, with low extractables and TOC’s, making it ideal for the manufacture of sterile pharmaceutical products.

When we talk about pioneers in adopting platinum cured silicone, Fluid Biosolutions stands tall. This commitment reflects their dedication to quality and customer-centricity. We ensure this applied to all of our products and services by applying the following:

Why is platinum cured silicone preferred in pharmaceutical processing?

How do Fluid Biosolutions utilise platinum cured silicone?

Is platinum cured silicone biocompatible?

What are the key differences between platinum cured and peroxide cured silicone?

Why are single-use systems gaining traction in the pharmaceutical industry?

How does platinum cured silicone enhance aseptic fluid management?

The unparalleled advantages of platinum cured silicone have set it apart in the realm of pharmaceutical processing. With industry leaders like Fluid Biosolutions championing its use, it’s clear that the future of drug manufacturing lies in embracing such innovative materials. Whether you’re a stakeholder in the pharmaceutical industry or a curious mind, the rise of platinum cured silicone is a testament to the industry’s commitment to quality, safety, and innovation.