Innovations in Bioreactor Design and Functionality

03 February 2025

Bioreactors are at the heart of many bioprocessing and pharmaceutical applications, providing controlled environments for cultivating cells, microorganisms, and biologics. Recent innovations in bioreactor design have transformed these systems, improving efficiency, scalability, and functionality. Here’s an overview of the most impactful advancements, and how they can enhance your processes.

1. Key Advancements in Bioreactor Technology

Modern bioreactors integrate several state-of-the-art features, including:

- Automated control systems: Precise management of variables such as temperature, pH, oxygen, and nutrients.

- Real-time data monitoring: Advanced sensors provide instant feedback, allowing for more accurate adjustments.

- Customised bioreactor designs: Tailored to specific processes, from microbial fermentation to cell culture.

These technologies make it easier to optimise bioprocesses, ensuring maximum yield and efficiency. Fluid Biosolutions offers a range of advanced bioreactor systems that support varied applications, ensuring businesses can meet production goals effectively.

2. Single-Use Bioreactors: A Game Changer

One of the most impactful innovations in recent years is the adoption of single-use bioreactors, which offer:

- Reduced contamination risks: Disposable components eliminate the need for cleaning and sterilisation.

- Quick turnaround times: Ideal for facilities with high production demand, allowing for faster batch-to-batch transitions.

- Lower costs: Savings on cleaning processes, sterilisation, and labour.

These single-use systems are perfect for flexibility and scalability, especially in environments where speed and safety are critical.

3. Optimising Bioreactor Performance for Higher Yields

Achieving high yields requires optimising key elements of bioreactor systems, such as:

- Efficient mixing systems: Ensures uniform nutrient distribution and gas exchange.

- Improved heat transfer: Keeps internal temperatures stable, which is critical for cell growth.

- Precision in monitoring: Automated systems ensure optimal conditions at all times.

At Fluid Biosolutions, our bioreactors are designed to deliver superior performance, ensuring consistent product quality across every batch.

4. The Importance of Silicone Tubing in Bioreactors

Silicone tubing is an essential component in bioreactors, facilitating the sterile transfer of fluids and gases. Key benefits of silicone tubing include:

- Flexibility and durability: Withstands temperature fluctuations and harsh conditions inside bioreactors.

- Biocompatibility: Ensures a sterile environment for cell growth, reducing contamination risks.

- High thermal stability: Withstands frequent sterilisation cycles without degrading.

Fluid Biosolutions provides high-purity silicone tubing that meets the stringent demands of the bioprocessing industry, ensuring your bioreactor systems remain efficient and safe.

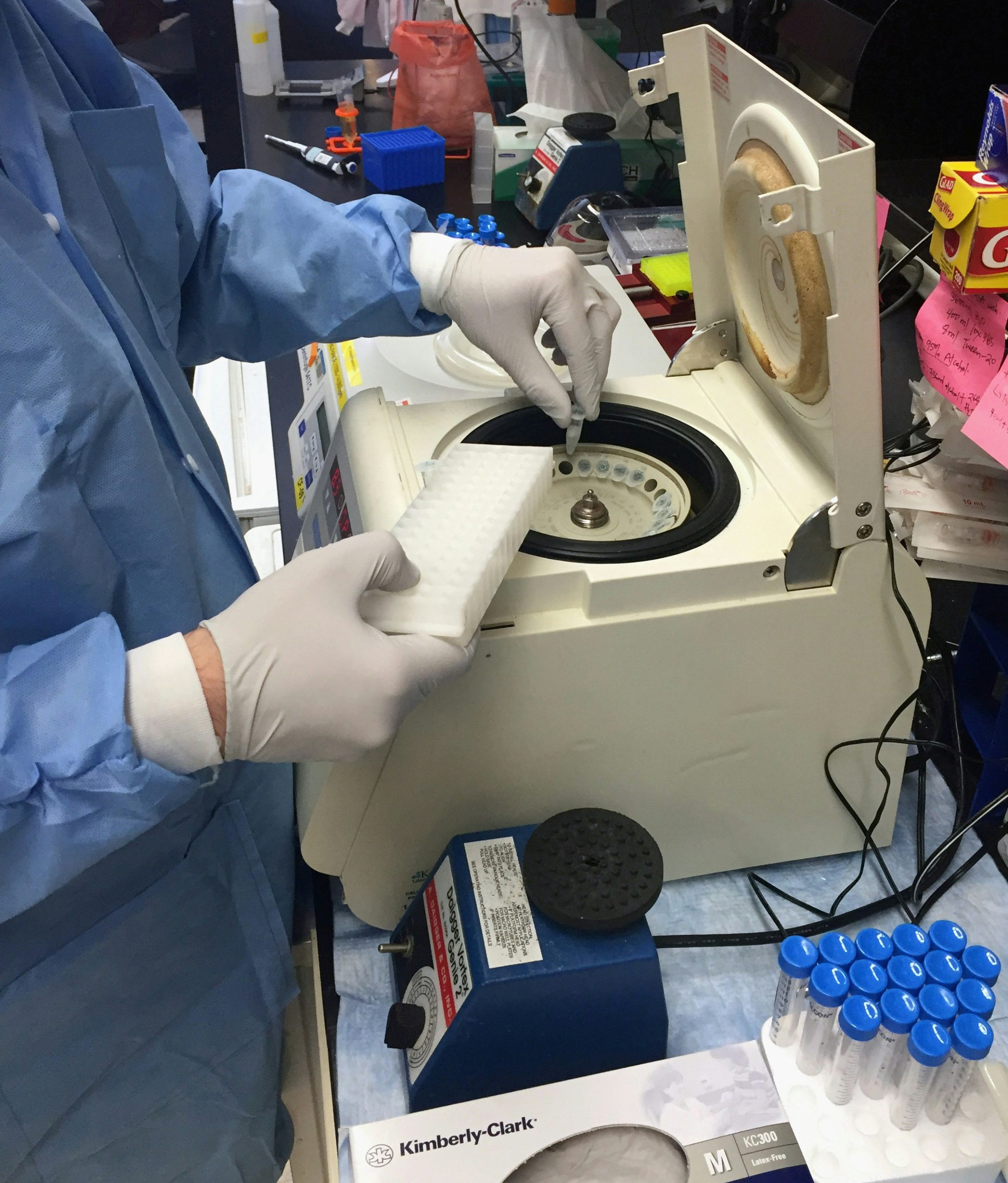

5. The Role of Centrifuge Machines in Bioreactor Systems

After cultivation, many processes rely on centrifuge machines for separating biological materials. Centrifuges help:

- Separate cells, proteins, and other substances quickly and efficiently.

- Maintain the integrity of biological products by offering high precision in separation.

- Improve downstream processing by working seamlessly with bioreactor outputs.

At Fluid Biosolutions, we offer reliable, high-performance centrifuge machines designed to complement bioreactor systems.

6. Automation and Smart Bioreactors

The integration of automation into bioreactors has revolutionised control and monitoring. Key benefits include:

- Remote monitoring: Allows for adjustments on-the-go, ensuring optimal conditions are maintained.

- Improved reproducibility: Automated systems reduce human error, making it easier to maintain consistency across batches.

- Data-driven insights: Advanced sensors and software provide real-time data, allowing businesses to refine their processes for better results.

Automation helps improve scalability and efficiency, ensuring that businesses can meet the growing demands of the biotech and pharmaceutical sectors.

7. Sustainability in Bioreactor Design

As environmental sustainability becomes a priority, innovations in bioreactor design are also focusing on:

- Energy efficiency: New bioreactor models consume less energy, reducing the environmental impact of bioprocessing.

- Modular designs: These allow for quicker scale-up or scale-down, minimising waste.

- Reduced material waste: Single-use systems help cut down on cleaning materials and water usage.

This trend towards sustainability not only benefits the environment but also reduces operational costs for businesses.

Conclusion: The Future of Bioreactor Systems

Innovations in bioreactor design are enabling biotech and pharmaceutical companies to produce better-quality products more efficiently. From single-use bioreactors to advanced automation, the latest trends in bioreactor technology offer tremendous potential for improving production processes. Combined with high-purity silicone tubing and centrifuge machines, these innovations help businesses achieve the highest levels of productivity and safety.

At Fluid Biosolutions, we’re dedicated to providing state-of-the-art bioreactor systems that meet the demands of modern biotechnology. Contact us today to optimise your bioprocessing systems.

Optimized by: Digital Six