Introduction to Centrifuge Technology in Biopharmaceuticals

20 March 2024

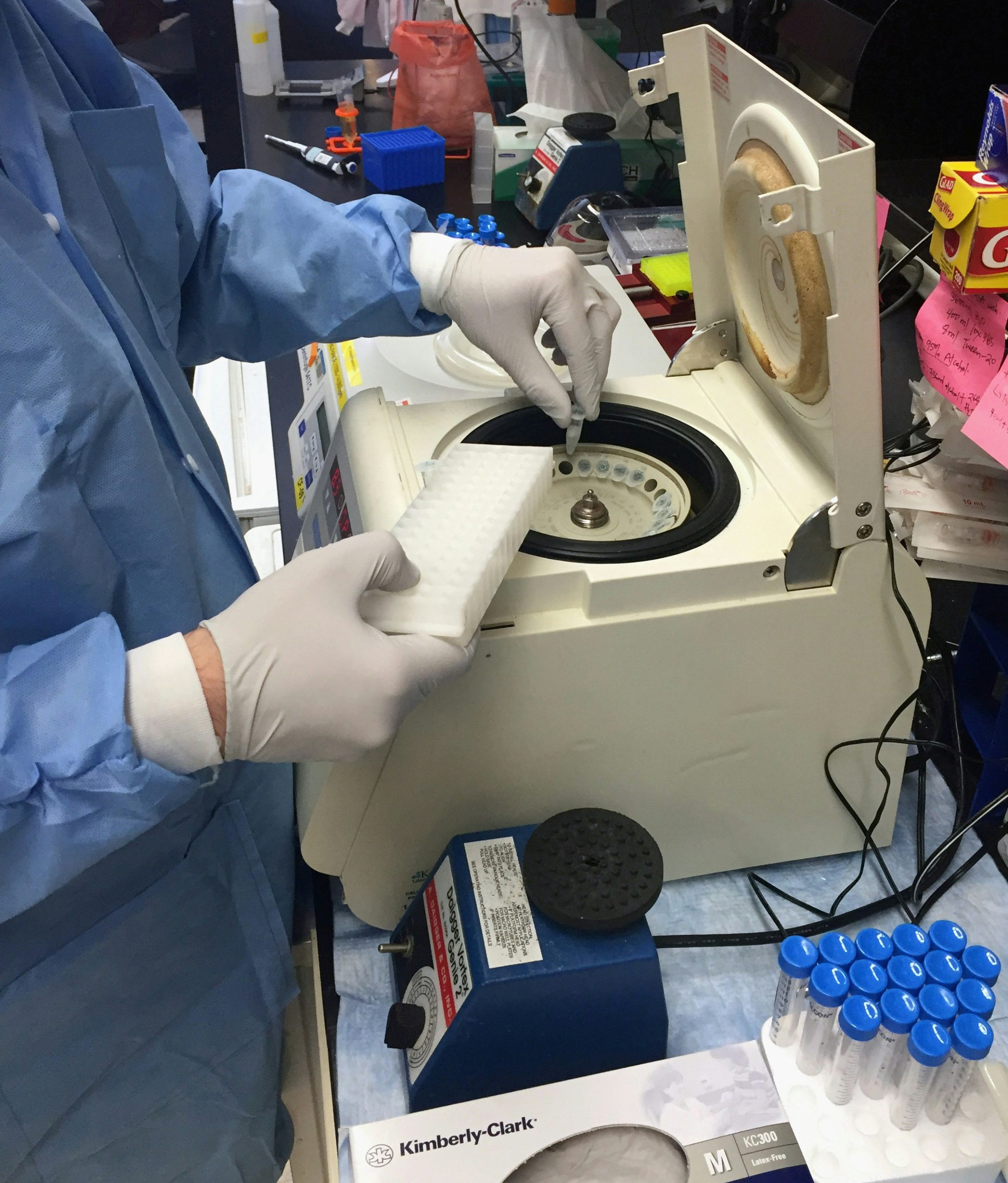

Centrifuges, known for their precision, efficiency, and adaptability, are instrumental in the processing and development of various biopharmaceuticals. In this comprehensive guide, we will explore the multifaceted role of centrifuges in biopharmaceutical processing, highlighting the latest innovations, benefits, applications, and how Fluid Biosolutions is spearheading these advancements.

The Critical Role of Centrifuges in Biopharmaceutical Processing

Centrifuges are vital in biopharmaceutical processing for their ability to separate and purify biological products. This includes a wide range of biological substances like vaccines, enzymes, monoclonal antibodies, and other biotherapeutics. Centrifuge technology has evolved to meet the industry’s demanding standards, offering solutions that maintain the integrity and purity of sensitive biological materials.

Innovations in Centrifuge Design and Functionality

Recent innovations in centrifuge technology have significantly enhanced their functionality in biopharmaceutical applications. These advancements include:

● Improved Rotor Designs: Modern centrifuges feature advanced rotor designs that maximise efficiency and minimise product damage.

● Enhanced Control Systems: State-of-the-art control systems in centrifuges allow for precise operation, optimising separation processes.

● Increased Automation: Automation has become a key feature in centrifuges, reducing manual intervention and increasing reproducibility.

Extended Applications of Centrifuges in Biopharmaceuticals

Centrifuge technology extends beyond basic separation tasks. Its applications in the biopharmaceutical industry include:

● Downstream Processing: Centrifuges are crucial in the downstream processing of biologics, including clarification, purification, and concentration steps.

● Cell Therapy and Regenerative Medicine: Centrifuges play a role in the preparation and processing of cell therapies and regenerative medicine.

● Virus Purification: Essential in the purification of viruses for vaccine development and viral vector-based therapies.

Advanced Benefits of Using Centrifuges

The benefits of using centrifuges in biopharmaceutical processing are extensive:

● Increased Yield and Purity: Advanced centrifuges deliver higher yields and purity levels in biopharmaceutical products.

● Operational Efficiency: Their design and automation capabilities make centrifuges highly efficient, reducing process times and labour costs.

● Scalability: Modern centrifuges can easily scale up from research to production, accommodating varying batch sizes.

Selecting the Perfect Centrifuge for Biopharmaceutical Needs

When selecting a centrifuge for biopharmaceutical processing, several factors need consideration:

● Operational Capacity: The centrifuge should match the scale of your biopharmaceutical processes.

● Compliance with Regulations: Ensure the centrifuge meets all relevant industry standards and regulatory requirements.

● Customizability: Some processes may require custom features or configurations in a centrifuge.

Maintaining and Optimising Centrifuge Performance

To ensure centrifuges operate at their best, regular maintenance and optimisation are necessary:

● Scheduled Maintenance: Regular maintenance schedules prevent unexpected downtime and prolong the life of the equipment.

● Performance Monitoring: Continuous monitoring helps in early detection of any potential issues.

● Staff Training: Proper training of staff in the operation and maintenance of centrifuges ensures optimal performance and safety.

The Future of Centrifuge Technology in Biopharmaceuticals

The future of centrifuge technology is bright, with ongoing research and development focusing on:

● Integration of Advanced Analytics: Incorporating advanced analytics for real-time monitoring and process optimisation.

● Sustainability Initiatives: Developing more energy-efficient and environmentally friendly centrifuge models.

● Customisation and Flexibility: Creating centrifuges that can be easily adapted to various biopharmaceutical processes.

Real-World Impact and Case Studies

To showcase the impact of centrifuges in the biopharmaceutical industry, here are additional case studies:

● Streamlining Biologic Drug Production: How a leading pharmaceutical company leveraged advanced centrifuges to streamline the production of biologic drugs, achieving higher efficiency and purity.

● Innovative Cell Therapy Processing: A case study of a biotech firm using centrifuges in innovative ways to process cell therapies, enhancing the quality and viability of therapeutic cells.

Conclusion

Centrifuge technology is an indispensable part of the biopharmaceutical industry, driving innovations and improvements in drug development and manufacturing. The advancements in centrifuge design and functionality are setting new standards in efficiency, purity, and scalability. As the industry continues to evolve, so will the capabilities and applications of centrifuges, making them even more vital to the future of biopharmaceutical processing.

For a closer look at how Fluid Biosolutions’ Centrifuge technologies can revolutionise your biopharmaceutical processes, visit our website or contact our expert team for a tailored solution.

Optimized by: Digital Six