Description

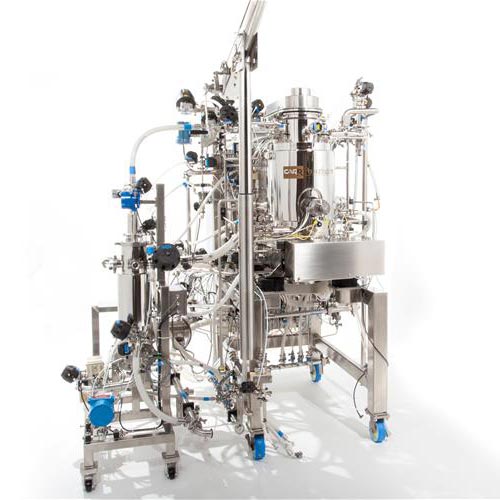

CARR Biosystem’s unique CARR Centritech Powerfuge P12 System provides continuous-flow two-phase separation of solids and liquids at rates up to 500 liters/ hour for batches up to 4,000 liters.

Using an innovative design, the feed is introduced through a stationary pipe and accelerated to full rotational speed before entering the titanium-alloy bowl. In this system, centrifugal forces as 20,000 g permit separation of even sub-micron particles. Compressed solids are periodically removed with a fully automated scraping cycle. After the solids have been discharged, automated CIP/SIP cycles can be performed via the PLC-controlled operating sequence.

The Powerfuge P12 is designed for ease operation, with seal feed and drain lines allowing for aerosol-free operation. Similarly, no special tools are required to disassemble the system. Integrated turnkey systems incorporating feed delivery options, CIP and SIP skids, temperature control, and closed-loop centrate pumping under vacuum are available.

The Powerfuge P12 system meets cGMP and CE requirements and has been validated to meet chemical and pharmaceutical industry protocols. The Powerfuge P12 is engineered to optimize ease of operation while maximizing throughput; each step in the process can be readily automated so that the time spent on routine maintenance can be minimized.

- Drier solids and clear liquids

- Sealed automatic operation

- Full CIP/SIP designs

- cGMP construction

- Designs available for ASME-rated boundary, hazardous locations, and aseptic operations

- State-of-the-art manufacturing facility located in Clearwater, Florida USA