The Essential Guide to Silicone Tubing for Bioprocessing Applications

24 September 2024Silicone tubing is a vital component in many industries, especially in the bioprocessing sector, where its flexibility, durability, and biocompatibility make it the material of choice. In applications such as biosolutions, centrifuges, and bioreactors, high-quality silicone tubing ensures smooth operations and maintains stringent safety standards. Whether you’re looking to optimise your processes or understand the benefits of silicone tubing, this guide will cover everything you need to know about how it can enhance your operations.

1. What is Silicone Tubing and Why Is It Essential?

Silicone tubing is made from a synthetic polymer with remarkable properties that suit various demanding applications. It stands out due to its thermal stability, flexibility, and non-reactivity, making it ideal for industries such as pharmaceuticals, food and beverage, and especially bioprocessing.

The bioprocessing sector, particularly in applications involving bioreactors and centrifuges, relies heavily on the smooth and sterile flow of fluids. This is where silicone tubing becomes essential, ensuring that bioprocesses remain contaminant-free while being resistant to heat, pressure, and chemicals. Additionally, the high purity of silicone tubing, such as the products available from Fluid Biosolutions, ensures that it complies with the most stringent industry standards.

2. Silicone Tubing in Biosolutions

In the world of biosolutions, where the integrity of biological substances must be preserved, silicone tubing plays a critical role. Whether you’re working with sensitive cell cultures or chemical compounds, the risk of contamination is significantly reduced when using high-purity tubing. Silicone tubing ensures a safe and sterile pathway, maintaining the quality of your processes.

At Fluid Biosolutions, our silicone tubing solutions offer unmatched performance for biosolution applications. For professionals working with bioreactors, silicone tubing allows the transport of fluids in a sterile and reliable manner, supporting the biomanufacturing processes from start to finish.

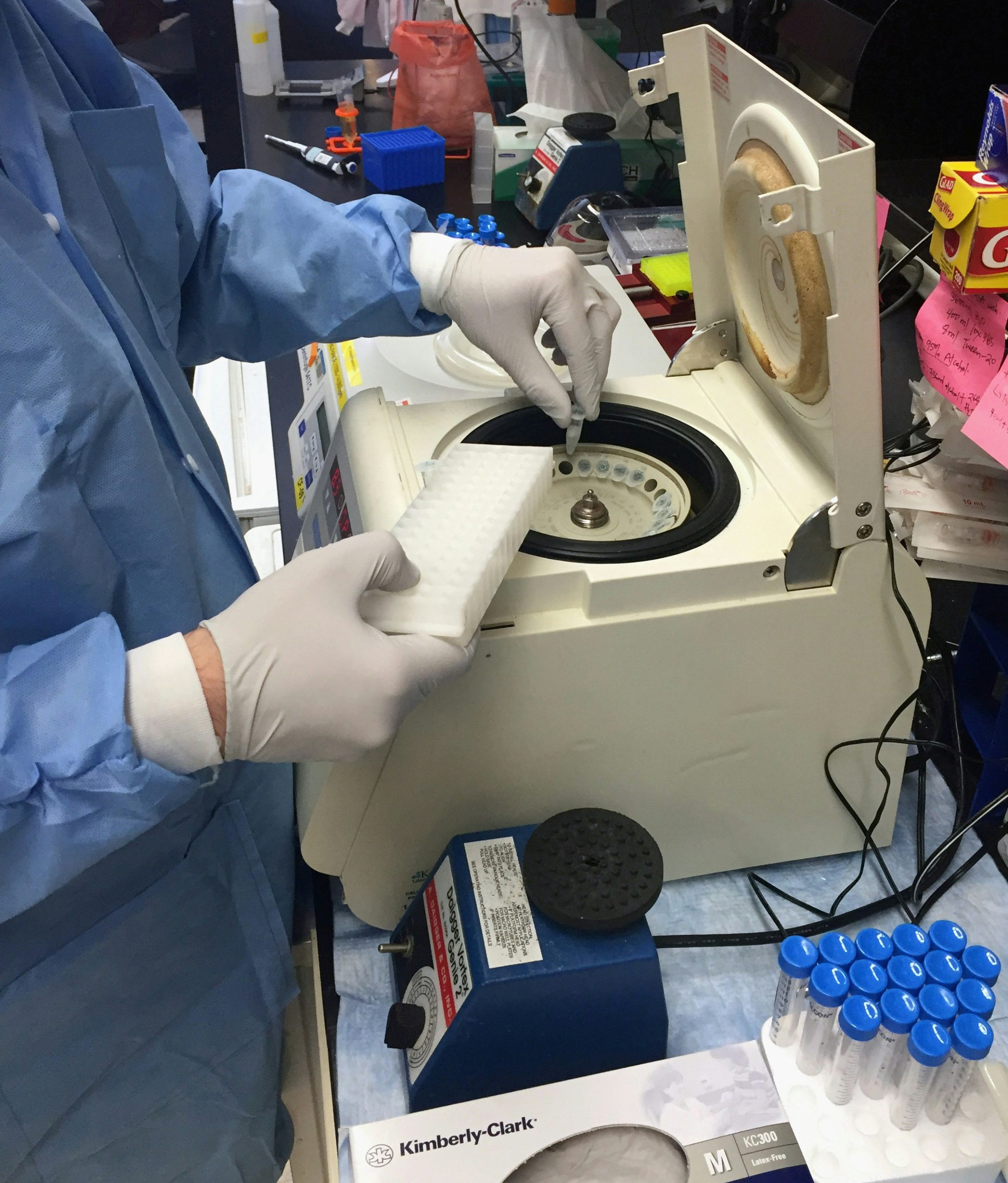

3. Key Benefits of Silicone Tubing for Centrifuges

Centrifuges are essential equipment in bioprocessing, used for separating different substances at high speeds. In these demanding conditions, tubing needs to withstand considerable forces while maintaining a steady flow of fluids. Silicone tubing’s elasticity and tear resistance make it the preferred choice for such high-speed environments.

Another advantage of silicone tubing in centrifuge operations is its ability to handle fluctuations in temperature and pressure without compromising fluid integrity. This reliability makes it ideal for industries where process control is critical. For more information about the specific products we offer, explore our high-purity tubing options.

4. Silicone Tubing in Bioreactors: Supporting Cell Growth

Bioreactors are controlled environments designed to cultivate cells, tissues, or microorganisms. These systems require the sterile transfer of gases and liquids, which is why silicone tubing is a key component in ensuring that these transfers occur smoothly and without contamination.

Due to its biocompatibility and resistance to harsh cleaning processes, silicone tubing is the go-to solution for bioreactor systems. Its ability to endure frequent sterilisation and cleaning cycles without degradation makes it the optimal choice for supporting sensitive biological processes. If you’re after bioreactor solutions or parts, our range of products is sure to have what you’re looking for. Find out more about this product here.

5. Why High-Purity Silicone Tubing Matters

Not all silicone tubing is created equal. High-purity silicone tubing, like the solutions available at Fluid Biosolutions, meets the stringent requirements of the pharmaceutical and bioprocessing industries.

- The material is tested to ensure low extractables, meaning it doesn’t release harmful substances into your process fluids.

- The use of high-purity tubing also ensures compliance with industry standards such as FDA, USP Class VI, and ISO 10993, which are crucial when working with pharmaceuticals or medical applications.

If you’re interested in upgrading your current tubing to meet higher standards, explore our range of high-purity silicone tubing.

6. Choosing the Right Silicone Tubing for Your Needs

Selecting the appropriate silicone tubing for your processes can be challenging, given the variety of options available. Factors to consider include:

- Size

- Material grade

- Pressure ratings.

Whether you’re working with bioreactors, centrifuges, or general biosolutions, it’s essential to choose tubing that aligns with your specific process requirements.

Our team at Fluid Biosolutions can help you select the right tubing for your applications, ensuring seamless integration with your current systems. For more information on our products and to speak to an expert, visit our contact page.

Conclusion

Silicone tubing is a critical component in the success of many bioprocessing applications. From biosolutions to bioreactors and centrifuges, high-quality silicone tubing ensures operational efficiency and safety. At Fluid Biosolutions, we offer a comprehensive range of high-purity silicone tubing designed to meet your specific industry needs.

If you’re ready to enhance your bioprocessing systems, get in touch with our team today or explore our range of high-purity tubing products.

Optimized by: Digital Six