Silicone Tubing’s Vital Role in Modern Medical Devices

27 March 2024Silicone tubing stands as a cornerstone in the realm of modern medical devices, playing a pivotal role in various applications critical for patient care and treatment. As the healthcare industry continues to evolve, the demand for innovative medical

devices equipped with silicone tubing remains steadfast. This article aims to delve into the multifaceted significance of silicone tubing in contemporary medical device design and functionality.

What is Silicone Tubing?

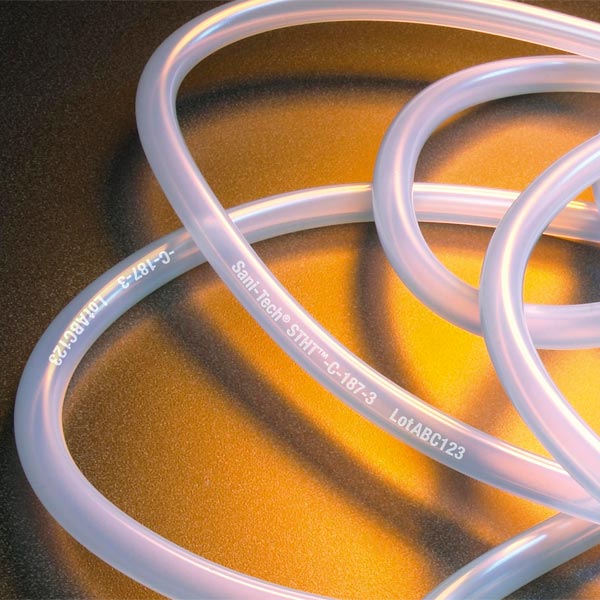

Silicone tubing is a flexible, hollow conduit made from silicone polymer, a synthetic material known for its exceptional biocompatibility and inertness. Unlike traditional materials such as rubber or plastic, silicone tubing offers a unique combination of properties ideal for medical applications. It boasts remarkable flexibility, durability, and resistance to a wide range of environmental factors, making it an indispensable component in various medical devices.

Applications of Silicone Tubing in Medical Devices

Silicone tubing finds extensive use across a spectrum of medical devices, facilitating critical functions in patient care and treatment:

● Intravenous (IV) Delivery Systems: Silicone tubing is integral to IV administration sets, providing a safe and reliable conduit for delivering fluids, medications, and nutrients directly into the bloodstream. Its flexibility and biocompatibility ensure seamless flow and minimal risk of adverse reactions.

● Peristaltic Pumps for Drug Delivery: Silicone tubing serves as the conduit in peristaltic pumps, which are commonly used for precise and controlled drug delivery in healthcare settings. The resilient nature of silicone tubing enables accurate dosing and consistent flow rates, essential for administering medications with precision.

● Catheters and Drainage Systems: Silicone tubing is a key component in catheters and drainage systems used for various medical procedures, including urinary catheterisation and wound drainage. Its softness, flexibility, and biocompatibility make it well-suited for prolonged contact with bodily tissues without causing irritation or discomfort.

Advantages of Silicone Tubing in Medical Devices

Silicone tubing offers several advantages that make it indispensable in medical device manufacturing:

● Biocompatibility and Inertness: Silicone tubing is biocompatible, meaning it is well-tolerated by the human body and does not elicit adverse immune responses. Its inert nature minimises the risk of tissue irritation, inflammation, or allergic reactions, making it suitable for prolonged contact with bodily fluids and tissues.

● Flexibility and Durability: Silicone tubing exhibits exceptional flexibility and resilience, allowing it to bend, twist, and stretch without compromising structural integrity. This flexibility is crucial in medical devices where tubing may need to conform to complex anatomical structures or undergo repetitive movements during use.

● Resistance to High and Low Temperatures, Chemicals, and Radiation: Silicone tubing demonstrates robust resistance to a wide range of environmental factors, including extreme temperatures, harsh chemicals, and radiation exposure. This resistance ensures the reliability and longevity of silicone tubing in medical devices, even in demanding operating conditions.

Customisation and Variability of Silicone Tubing

Silicone tubing offers a high degree of customisation and variability to meet the diverse needs of medical device manufacturers:

● Various Sizes, Shapes, and Configurations: Silicone tubing is available in a wide range of sizes, ranging from microbore tubing used in minimally invasive procedures to larger diameters for high-volume fluid transfer applications. Additionally, manufacturers can choose from various shapes and configurations, including round, square, or rectangular cross-sections, to suit specific device requirements.

● Customisation Options for Specific Medical Device Requirements: Medical device manufacturers can customise silicone tubing to meet the exact specifications of their devices. This includes tailoring properties such as durometer (hardness), wall thickness, and colour to optimise performance and functionality. Customised silicone tubing ensures a perfect fit and seamless integration within the medical device assembly.

● Importance of Selecting the Right Type of Silicone Tubing for Each Application: With the availability of customisable options, it’s essential for manufacturers to select the right type of silicone tubing for each application.

Factors such as intended use, compatibility with other components, and regulatory requirements must be carefully considered to ensure optimal performance and patient safety.

Regulatory Considerations for Silicone Tubing in Medical Devices

Regulatory considerations play a pivotal role in the utilisation of silicone tubing within medical devices:

Compliance with Medical Device Regulations and Standards is paramount. Manufacturers must adhere to standards like ISO 13485 for quality management systems and ISO 10993 for biocompatibility testing. These standards ensure the production of safe and reliable medical devices.

Biocompatibility Testing and Validation are crucial steps in silicone tubing manufacturing. Testing assesses the material’s compatibility with biological systems, including cytotoxicity, sensitisation, and irritation tests, ensuring patient safety.

Regulatory Requirements for Sterilisation and Packaging are stringent. Silicone tubing must undergo sterilisation to eliminate microorganisms and maintain sterility until use. Compliance with validated sterilisation processes and appropriate packaging protocols is essential for patient safety.

These regulatory considerations underscore the importance of meticulous quality control and adherence to standards throughout the manufacturing process. By meeting regulatory requirements, manufacturers can ensure the safety, efficacy, and

compliance of medical devices containing silicone tubing.

Case Studies: Real-world Examples of Silicone Tubing in Medical Devices

Real-world case studies provide insight into the diverse applications of silicone tubing in medical devices:

● Case Study 1: Intravenous (IV) Delivery Systems: A medical device company developed an innovative IV administration set incorporating silicone tubing. The flexibility and biocompatibility of the silicone tubing enabled smooth fluid delivery, reducing the risk of complications for patients receiving intravenous therapy.

● Case Study 2: Catheters and Drainage Systems: A healthcare facility implemented silicone tubing-based catheters and drainage systems for patient care. The softness and durability of the silicone tubing contributed to patient comfort and device longevity, enhancing the overall quality of care.

These case studies highlight the crucial role of silicone tubing in enhancing the performance and reliability of medical devices across various healthcare settings.

Future Trends and Innovations in Silicone Tubing for Medical Devices

Ongoing advancements in silicone tubing technology pave the way for future innovations in medical device design and functionality:

● Emerging Technologies and Materials: Researchers are exploring novel materials and manufacturing techniques to enhance the properties of silicone tubing. Advancements in material science and nanotechnology may lead to silicone tubing with improved strength, flexibility, and biocompatibility.

● Potential Advancements in Design and Functionality: Future silicone tubing designs may incorporate features such as integrated sensors for real-time monitoring of patient parameters or drug delivery systems with customisable flow rates. These innovations have the potential to revolutionise medical device capabilities and patient care outcomes.

By staying at the forefront of technological advancements and collaborating with industry partners, manufacturers can drive innovation in silicone tubing for medical devices, ultimately improving patient outcomes and advancing healthcare delivery.

Conclusion

Silicone tubing stands as a cornerstone in modern medical device manufacturing, offering unparalleled flexibility, biocompatibility, and durability. Its diverse applications, ranging from IV delivery systems to catheters and drainage systems,

underscore its vital role in patient care and treatment.

As we navigate the complexities of healthcare delivery, silicone tubing continues to drive innovation and improve medical device performance. From compliance with regulatory standards to the integration of emerging technologies, manufacturers are leveraging silicone tubing to enhance patient outcomes and elevate the standard of care.

Ready to incorporate high-quality silicone tubing into your medical devices?

Contact Fluid Biosolutions today to explore our range of silicone tubing solutions. Let us partner with you to develop innovative medical devices that prioritise patient safety, comfort, and efficacy. Together, we can shape the future of healthcare.

Optimized by: Digital Six