Unlocking the Potential of Bioreactors in Biopharmaceuticals

04 May 2024

Welcome to our in-depth exploration of bioreactors, a key technology in the biopharmaceutical industry. Bioreactors, known for their efficiency, precision, and versatility, play an essential role in developing therapeutic drugs and vaccines. In this article, we’ll delve into the different types of bioreactors, their applications in biopharmaceuticals, and why they are indispensable for advancing medical science.

To learn more about our cutting-edge bioreactor solutions and how they can revolutionise your biopharmaceutical processes, contact Fluid Biosolutions.

Overview of Bioreactors in Biopharmaceuticals

Bioreactors are at the heart of biopharmaceutical manufacturing, renowned for their ability to cultivate cells or microorganisms under controlled conditions. These sophisticated systems are designed to maintain optimal environments for biological reactions, ensuring high yields of the desired bioproduct. The precise control over parameters such as temperature, pH, oxygen, and nutrient levels is what sets bioreactors apart, making them integral in producing vaccines, antibodies, and other

therapeutic substances.

Types and Benefits of Bioreactors

Bioreactors come in various forms, each suited to specific applications:

● Stirred-Tank Bioreactors: Widely used due to their versatility and scalability. Ideal for large-scale production of proteins and vaccines.

● Airlift Bioreactors: Known for their simplicity and low shear stress, perfect for fragile cell cultures.

● Fluidised Bed Bioreactors: Excellent for immobilised cells, offering high mass transfer rates and operational stability.

● Wave Bioreactors: Utilise a rocking motion for mixing, reducing shear stress. They are perfect for sensitive cell cultures.

The selection of a bioreactors, type depends on several factors, including the nature of the biological system, production scale, and desired product characteristics.

Applications in Biopharmaceuticals

Bioreactors are crucial in numerous biopharmaceutical processes:

● Monoclonal Antibody Production: Key in cultivating mammalian cells for antibody production.

● Vaccine Manufacturing: Essential for growing virus or bacteria cultures in vaccine development.

● Cell Therapy and Regenerative Medicine: Used in growing stem cells and other therapeutic cells.

● Enzyme Production: Ideal for producing enzymes in high quantities.

● Biosimilar Development: Central to developing biosimilars, which require precise environmental control.

Choosing the Right Bioreactor

Selecting the ideal bioreactors, involves considering:

● Scale of Production: Assess whether the bioreactor can handle the required production scale.

● Cell Type Compatibility: Ensure the bioreactor is suitable for the specific cells used.

● Operational Parameters: Check if the bioreactor can maintain the necessary environmental conditions.

● Compliance and Standards: Ensure the bioreactor meets regulatory standards and industry certifications.

Maintenance and Care Tips for Bioreactors

Proper maintenance is vital for the performance and longevity of bioreactors:

● Routine Checks: Regularly monitor for any signs of wear or operational issues.

● Cleaning and Sterilisation: Implement strict cleaning protocols to maintain sterility.

● Calibration: Regularly calibrate sensors and control systems.

● Documentation and Record-Keeping: Maintain detailed records of all operations and maintenance activities.

Innovations and Future Trends

The biopharmaceutical industry is continuously evolving, and so are bioreactor technologies. Recent advancements include the development of single-use bioreactors, which offer increased flexibility and reduced contamination risk.

Additionally, the integration of advanced sensors and control systems for real-time monitoring and process optimisation is on the rise. The future may also see an increased focus on sustainable and energy-efficient bioreactor designs.

Real-World Impact of Bioreactors

Bioreactors have been instrumental in several breakthroughs:

● Rapid Vaccine Development: Enabled swift response in vaccine production during global health crises.

● Advanced Therapeutics: Facilitated the development of personalised medicine and targeted therapies.

● Increased Production Efficiency: Enhanced yield and quality of biopharmaceutical products.

In conclusion, bioreactors are a cornerstone of the biopharmaceutical industry. Their ability to precisely control biological processes makes them invaluable in the production of lifesaving drugs and therapies. As biotechnology advances, bioreactors will continue to play a critical role in the development of new and improved medical treatments.

For a comprehensive range of bioreactor solutions and to discover how we can tailor them to your specific needs, visit Fluid Biosolutions.

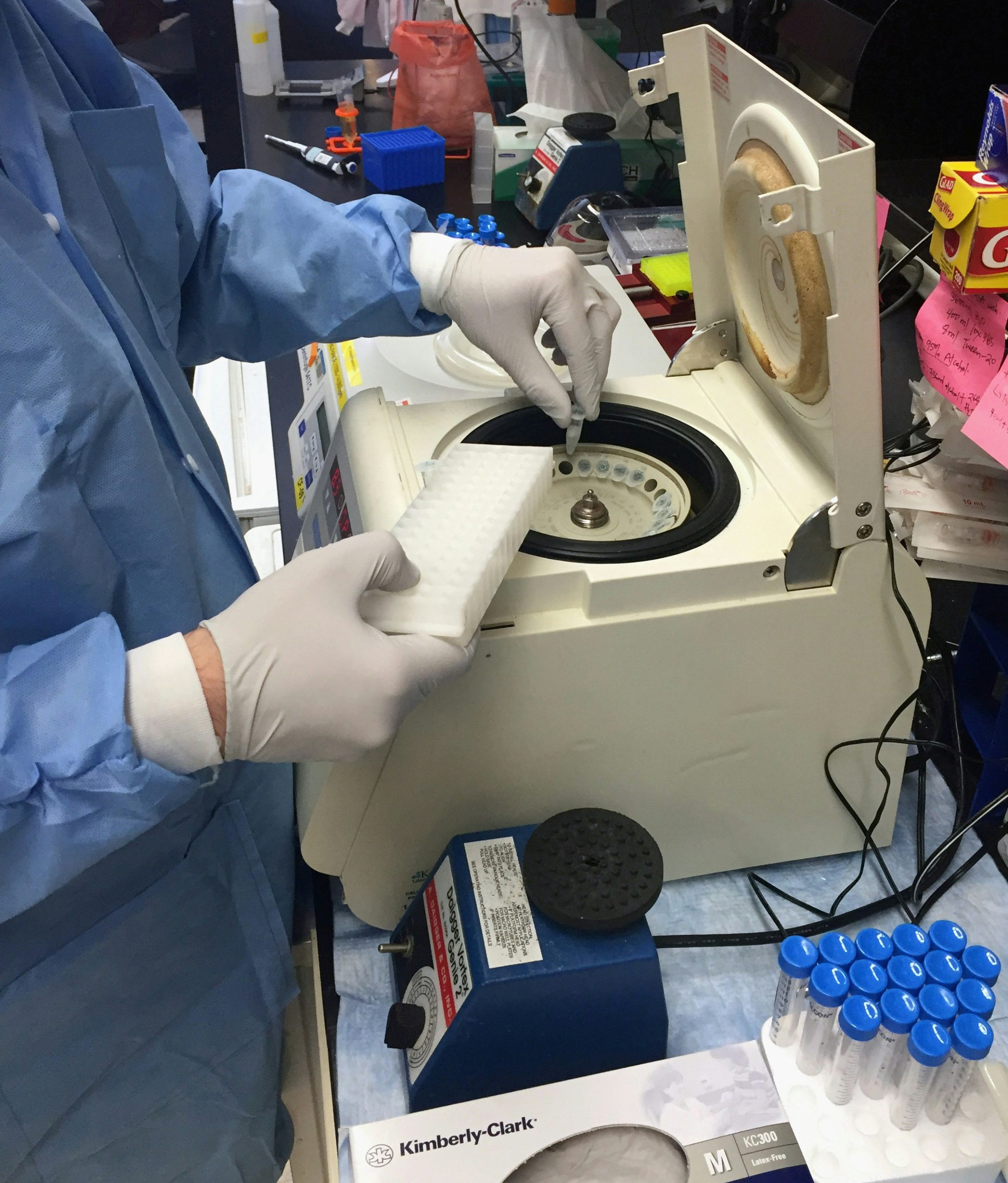

Contact our expert team today to find out more about our innovative solutions, including our high-quality platinum cured silicone and silicone tubing products, as well as our advanced centrifuge technologies.

Optimized by: Digital Six