Understanding the Durability and Flexibility of Silicone Tubing for Fluid Transfer: A Comprehensive Guide

20 March 2024In the world of fluid transfer, the choice of tubing material can significantly impact the efficiency, safety, and quality of the process. Silicone tubing, with its standout qualities of being both tough and adaptable, has emerged as a frontrunner. But what exactly makes silicone tubing so special? In this blog, we’re going beyond the surface to explore how silicone tubing excels in applications where dependability is key. Join us as we unpack the reasons behind its popularity across various sectors, from healthcare to your local brewery.

Summary of Contents:

In this in-depth look at silicone tubing, we’ll cover:

1. Why Silicone?: Your blog opens with an introduction that sets the stage for why silicone tubing is a superior choice, matching the first point of your summary.

2. Durability Defined: You have a section titled “Understanding Durability in Silicone Tubing” that explains why silicone tubing is so durable, directly aligning with the “Durability Defined” point.

3. Flexibility in Action: The section “The Flexibility of Silicone Tubing” perfectly encapsulates the flexibility aspect, as outlined in your summary.

4. A Sector-by-Sector Breakdown: Your “Industry Applications” segment provides a detailed look into how silicone tubing benefits various industries, just as promised in the summary.

5. Saint-Gobain Life Sciences Excellence: The dedicated section on Saint-Gobain Life Sciences’ silicone tubing highlights the partnership and product quality, matching the summary point.

6. Silicone vs. The Rest: The comparative analysis of silicone tubing against other materials like PVC, latex, or polyurethane is well-covered under “Comparing Silicone Tubing with Other Materials.”

7. Keeping it Prime: Maintenance advice is provided in the “Maintenance and Care for Silicone Tubing” section, ensuring readers know how to prolong their silicone tubing’s lifespan.

8. Your Questions, Answered: Lastly, the “Frequently Asked Questions” section addresses common inquiries, providing clarity and additional information as indicated in your summary.

The Significance of Silicone Tubing in Fluid Transfer Silicone tubing, known for its resilience and elastic nature, has become an indispensable component in various applications, from medical devices to food and beverage processing. Its unparalleled flexibility allows it to bend and stretch without losing its shape or integrity, making it ideal for systems requiring tight turns and complex routing. Moreover, the durability of silicone tubing ensures that it can withstand repeated use and exposure to harsh conditions without degrading, a critical factor for industries that demand high standards of hygiene and performance.

Understanding Durability in Silicone Tubing

At the heart of silicone tubing’s durability is its robust material composition. Silicone, a synthetic rubber, possesses a unique molecular structure that gives it resistance to extreme temperatures, UV light, and chemicals. This resilience makes silicone tubing a preferred choice in environments where exposure to aggressive substances or extreme conditions is common. Whether it’s transferring steam in sterilisation processes or handling corrosive fluids in chemical manufacturing, silicone tubing maintains its integrity, ensuring a safe and uninterrupted flow of materials.

The Flexibility of Silicone Tubing

Flexibility is another hallmark of silicone tubing, enabling its use in a variety of demanding applications. Unlike rigid materials that can crack or break under pressure, silicone tubing offers superior elasticity, allowing it to be fitted around obstacles and into tight spaces with ease. This flexibility does not come at the expense of strength; silicone tubing can withstand significant pressure variations and pulsations, ensuring a reliable conduit for fluids under varying operational conditions.

Industry Applications

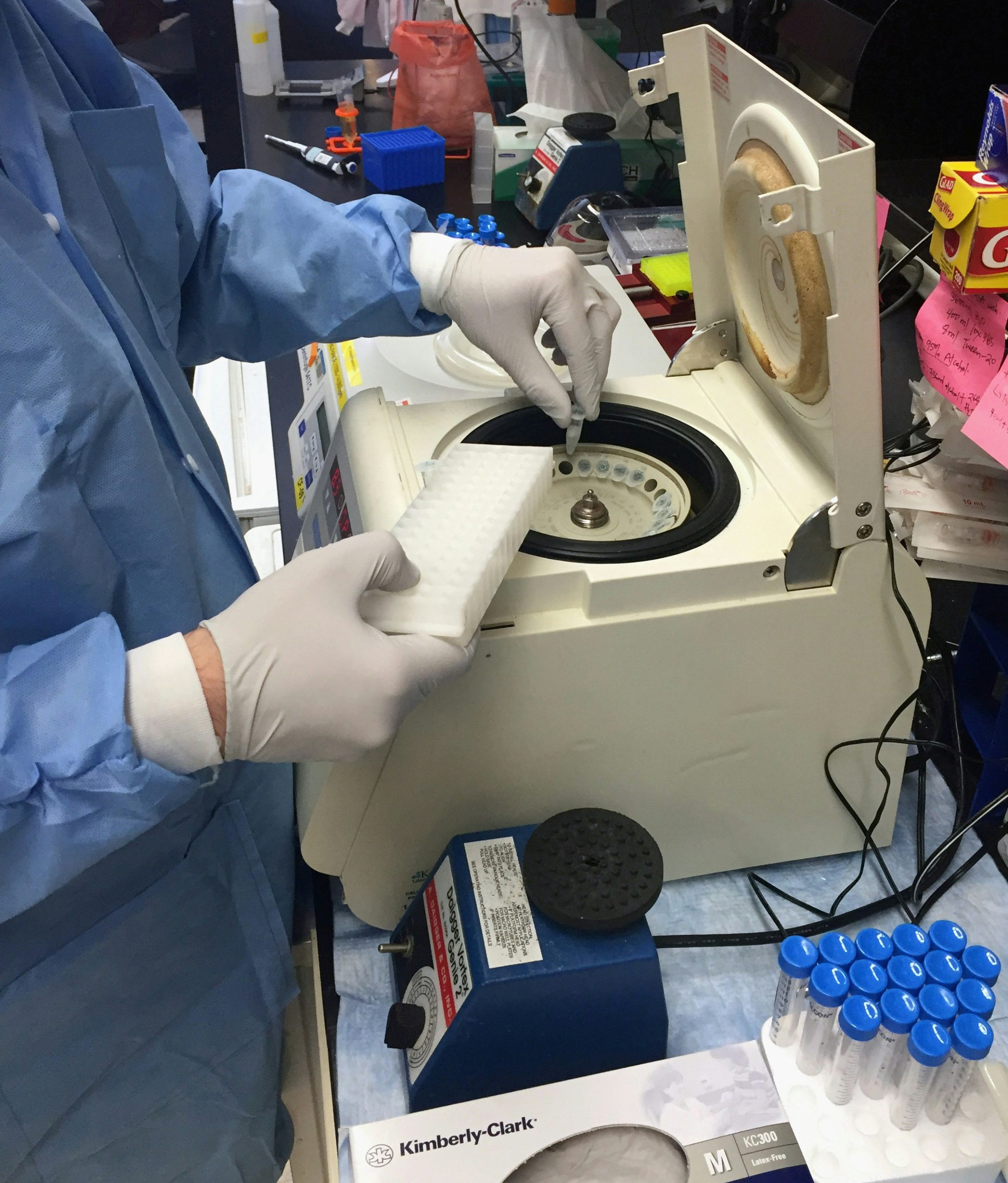

Silicone tubing’s versatility shines across numerous sectors. In the medical field, it’s used for intravenous (IV) lines and catheters, thanks to its biocompatibility and sterilisation factors. The pharmaceutical industry relies on it for drug delivery systems, where purity and precision are paramount. In the food and beverage sector, silicone’s non-toxic, tasteless, and odourless qualities make it perfect for transferring consumables without affecting quality or safety. Additionally, its thermal stability is crucial in aerospace and automotive industries for coolant and fuel lines that can withstand extreme temperatures.

Spotlight on Quality: Saint-Gobain Life Sciences‘ Silicone Tubing

At the heart of our commitment to providing superior fluid transfer solutions at Fluid Biosolutions is our partnership with Saint-Gobain Life Sciences. Renowned for their pioneering spirit and commitment to quality, Saint-Gobain Life Sciences brings to the table a range of silicone tubing products that set the bar in the industry. Their dedication to innovation is evident in every piece of silicone tubing they produce, designed to meet the rigorous demands of various applications—from medical and pharmaceutical processes to food and beverage production.

Saint-Gobain Life Sciences’ silicone tubing is engineered for resilience and versatility, ensuring operations are not just efficient but also safe and compliant with industry standards. This commitment to excellence makes Saint-Gobain’s products a cornerstone of our offerings, giving our clients access to fluid transfer solutions that truly stand the test of time. By choosing silicone tubing from Saint-Gobain Life Sciences, available through Fluid Biosolutions, you’re selecting a product that embodies durability and flexibility, essential for challenging environments and critical applications.

Comparing Silicone Tubing with Other Materials

When compared to materials like PVC, latex, or polyurethane, silicone tubing offers superior flexibility and durability, especially in extreme conditions. PVC, while cost-effective, lacks the temperature range and chemical resistance of silicone. Latex can trigger allergic reactions and degrades more quickly over time. Polyurethane offers good flexibility but doesn’t match silicone’s comprehensive resistance to heat, UV, and chemicals. These comparisons highlight why silicone tubing is often the preferred choice for demanding applications.

Maintenance and Care for Silicone Tubing

To maximise the lifespan and performance of silicone tubing, proper maintenance is crucial. Regular cleaning with mild soap and water is sufficient for most applications, followed by thorough drying. For medical or food-grade tubing, sterilisation methods such as autoclaving, gamma irradiation, or ethylene oxide (EtO) gas can be employed, depending on the manufacturer’s specifications. It’s also important to store silicone tubing away from direct sunlight and extreme temperatures to prevent premature ageing.

Frequently Asked Questions

Q: Can silicone tubing be used for high-pressure applications?

● A: Yes, silicone tubing can handle a range of pressures, but it’s essential to select the right wall thickness and reinforcement for the application.

Q: Is silicone tubing resistant to all chemicals?

● A: While silicone tubing is resistant to many chemicals, its compatibility can vary. It’s important to consult compatibility charts or the manufacturer for specific substances.

Q: How long does silicone tubing last?

● A: The lifespan of silicone tubing depends on the application, including factors like temperature, chemical exposure, and mechanical stress. With proper care, it can last several years.

Conclusion

In the demanding world of fluid transfer, where efficiency, safety, and quality are paramount, the choice of tubing material is critical. Silicone tubing, with its unmatched durability and flexibility, rises above alternatives like PVC, latex, or polyurethane, proving itself time and again in the most challenging environments. At Fluid Biosolutions, we understand the importance of reliable fluid transfer solutions across all industries—from medical and pharmaceutical to food and beverage, and beyond. Our extensive range of high-quality silicone tubing products is crafted to meet the highest standards, ensuring your operations run smoothly and safely.

Choosing the right silicone tubing can dramatically impact the success of your applications, delivering superior performance where other materials fall short. Our silicone tubing solutions are designed to cater to your specific needs, offering a blend of durability and flexibility that is hard to find elsewhere. By partnering with Fluid Biosolutions, you’re not just selecting a product; you’re choosing peace of mind, knowing that your fluid transfer requirements are in expert hands.

We invite you to explore our silicone tubing offerings and discover how we can enhance your operations with our tailored solutions. For further information or to discuss your needs in detail, contact us today. Let’s work together to achieve optimal results in safety, efficiency, and cost-effectiveness, ensuring your operations excel in every aspect.

Optimized by: Digital Six