The Ultimate Guide to Silicone Tubing in Pharmaceutical Applications

15 December 2023

Welcome to our comprehensive guide on silicone tubing, a crucial component in the pharmaceutical industry. Silicone tubing, known for its flexibility, durability, and chemical inertness, plays a pivotal role in various pharmaceutical processes. In this guide, we will discuss why silicone tubing is the preferred choice for pharmaceutical applications, covering its benefits, applications, and maintenance. To discover more about our high-purity silicone tubing and how it can enhance your pharmaceutical operations, contact Fluid Biosolutions today.

Overview of Silicone Tubing in Pharmaceuticals

Silicone tubing is a cornerstone in the pharmaceutical industry, prized for its exceptional properties. It stands out for its remarkable flexibility, making it ideal for various fluid transfer applications. Additionally, its inert nature ensures that it does not react with medications or biological samples, preserving their purity. The tubing’s ability to withstand a wide range of temperatures, from extreme cold to intense heat, without degradation, is crucial for maintaining the integrity of sensitive pharmaceutical products. These features make silicone tubing indispensable in pharmaceutical manufacturing and research labs.

Benefits of Using Silicone Tubing

One of the key benefits of silicone tubing in pharmaceutical applications is its non-reactivity. This property is crucial as it ensures that the tubing does not leach chemicals into the products or react with the substances it transports. This is particularly important in the pharmaceutical industry, where product purity is paramount. Silicone tubing is also known for its excellent thermal stability. It can operate in a wide temperature range without losing its flexibility or structural integrity, making it ideal for processes involving heat sterilisation.

Another advantage is its longevity and durability. Silicone tubing can withstand repeated use and sterilisation processes without degrading, making it a cost-effective and reliable choice for long-term use. Furthermore, its translucency allows for easy monitoring of fluid flow, which is essential in many pharmaceutical operations.To explore our range of silicone tubing, please visit our silicone tubing page here.

Applications in the Pharmaceutical Industry

Silicone tubing is extensively used in various pharmaceutical operations. Its application ranges from being a part of peristaltic pumps, which are essential for moving fluids through processes without contamination, to its use in drug delivery systems where precision and purity are critical. In laboratories, silicone tubing is used in applications requiring high levels of cleanliness and non-toxicity, such as in the handling of sensitive biological samples. Its versatility also extends to being used in manufacturing processes, where it aids in the safe transfer of raw materials and finished products. Please see below examples of specific applications of silicone tubing in the pharmaceutical industry:

- Peristaltic Pumps: Used in fluid transfer to prevent contamination.

- Drug Delivery Systems: Ensures accurate and contamination-free delivery of medications.

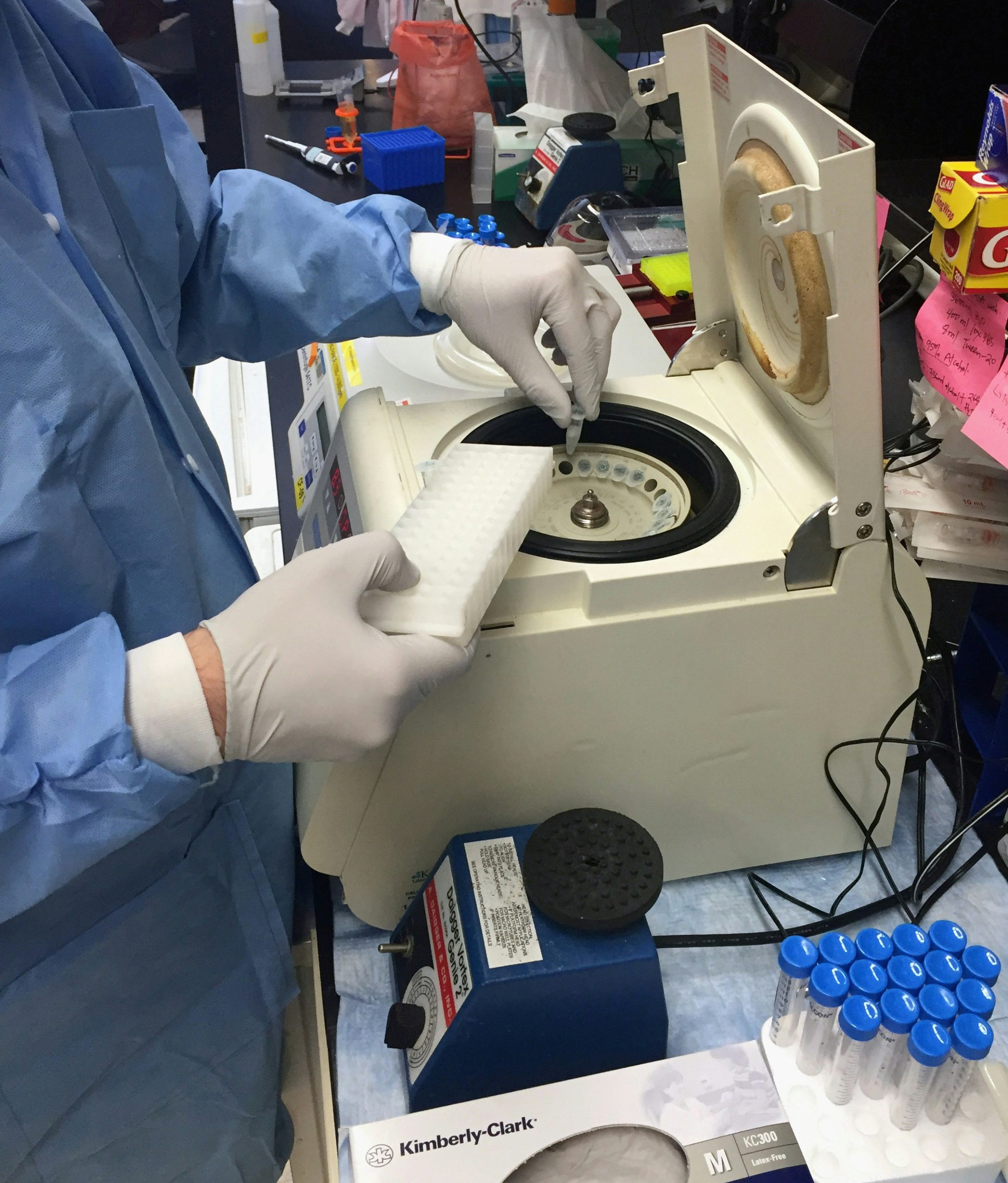

- Laboratory Research: For handling sensitive biological samples, where cleanliness and non-toxicity are crucial.

- Bioreactors: In the cultivation of cells or microorganisms under controlled conditions.

- Sterile Filling: Essential in the aseptic filling of pharmaceutical products.

- Diagnostic Equipment: Used in equipment where precision and reliability are vital.

Selecting the Right Silicone Tubing

Choosing the appropriate silicone tubing for pharmaceutical applications involves several key considerations:

- Material Quality and Purity: Ensure the tubing is made from high-quality, medical-grade silicone.

- Size and Flexibility: Select tubing with the correct inner and outer diameters for your specific application, and consider the flexibility required.

- Chemical Compatibility: Make sure the silicone tubing is compatible with the chemicals and substances it will come into contact with.

- Temperature Resistance: Consider the temperature range the tubing will be exposed to, ensuring it can withstand the operational extremes.

- Certifications and Standards Compliance: Verify that the tubing meets industry standards and certifications, such as USP Class VI, FDA, or similar.

Maintenance and Care Tips for Silicone Tubing

Proper maintenance is crucial for maximising the lifespan and effectiveness of silicone tubing in pharmaceutical applications:

- Regular Inspection: Regularly inspect tubing for signs of wear, tear, or degradation.

- Cleaning Protocols: Implement appropriate cleaning procedures, ensuring the use of compatible cleaning agents.

- Proper Storage: Store silicone tubing in a cool, dry place away from direct sunlight and harsh chemicals.

- Handling Precautions: Handle with care to prevent punctures or tears, especially when connecting or disconnecting from equipment.

- Sterilisation: Follow recommended sterilisation procedures, considering the specific type of silicone tubing used.

Innovations and Future Trends in Silicone Tubing Technology

The pharmaceutical industry is at the forefront of innovation, and this extends to the development of silicone tubing technologies. There is ongoing research into new silicone compounds that promise enhanced performance characteristics, especially in terms of durability and chemical compatibility. Moreover, customisation is becoming increasingly important, with tubing solutions being tailored to meet the unique requirements of specific pharmaceutical applications.

Looking ahead, the integration of smart technology in silicone tubing is a potential trend. This could involve embedding smart sensors within the tubing to monitor fluid properties in real-time, offering unprecedented levels of control and safety. Additionally, in response to global environmental concerns, there is a growing focus on developing more eco-friendly silicone tubing options. These advancements not only promise to improve the functionality of silicone tubing but also align with the sustainability goals of the pharmaceutical industry.

Case Studies and Real-World Examples

To illustrate the impact of silicone tubing in the pharmaceutical industry, let’s explore a few case studies:

- Innovative Drug Delivery: A pharmaceutical company used custom-designed silicone tubing in a novel drug delivery system, resulting in increased efficiency and patient safety.

- Bioreactor Efficiency: A biotech firm incorporated silicone tubing in their bioreactors, enhancing the cultivation process of microbial cultures with improved sterility and temperature control.

- Laboratory Research Breakthroughs: Several research labs reported significant improvements in sample integrity and experimental accuracy after switching to high-quality silicone tubing.

Each of these examples demonstrates the versatility and effectiveness of silicone tubing in real-world pharmaceutical applications.

In conclusion, silicone tubing stands as a pivotal element in the pharmaceutical industry, known for its versatility, safety, and efficiency. From enhancing drug delivery systems to improving laboratory research, its impact is widespread and crucial. As we have seen, advancements in this field continue to push the boundaries, promising even more innovative applications in the future. For those in the pharmaceutical sector, understanding and utilising the benefits of high-quality silicone tubing is not just an option, but a necessity for continued success and innovation.

Remember, for all your silicone tubing needs, explore our extensive range at Fluid BioSolutions’ High-Purity Tubing and Hoses.

To find out more about how we can create a customized solution for your needs, contact our friendly team here.

Optimized by: Digital Six