Understanding Centrifuge Mechanics: A Deep Dive Into Rotational Separation

01 July 2024

Introduction: Unravelling the Mysteries of Centrifugation

In the realm of scientific discovery and industrial efficiency, the centrifuge stands as a pivotal tool, elegantly separating components with its rotational prowess. At Fluid BioSolutions, we understand the critical role centrifuges play in diverse sectors. This deep dive into centrifuge mechanics aims to enlighten our readers on the intricacies of this essential equipment, from its historical origins to the latest technological advancements.

Discover our range of centrifuges, each embodying the pinnacle of design and functionality.

Centrifugal Force: The Heartbeat of Every Centrifuge

At its core, the centrifuge operates on a fundamental principle: centrifugal force. This force, a cornerstone in the functionality of every centrifuge, emerges when an object rotates around a central point, moving away due to inertia. In the context of a centrifuge, this translates to the rapid spinning of samples, which leads to the effective separation of components based on their density.

As a centrifuge spins, denser particles move outward, settling against the outer walls of the bowl, while lighter components remain closer to the centre. This elegant yet powerful mechanism enables precise separation in myriad applications, from medical diagnostics to environmental analysis.

The centrifuge’s versatility lies in its ability to be tailored for specific tasks. Variations in speed, rotor type, and duration of spin allow for the meticulous separation of different substances, highlighting the centrifuge’s indispensable role in scientific and industrial fields.

Exploring the Spectrum: Diverse Types of Centrifuges

Centrifuges come in various forms, each designed to cater to specific requirements. The most common types include:

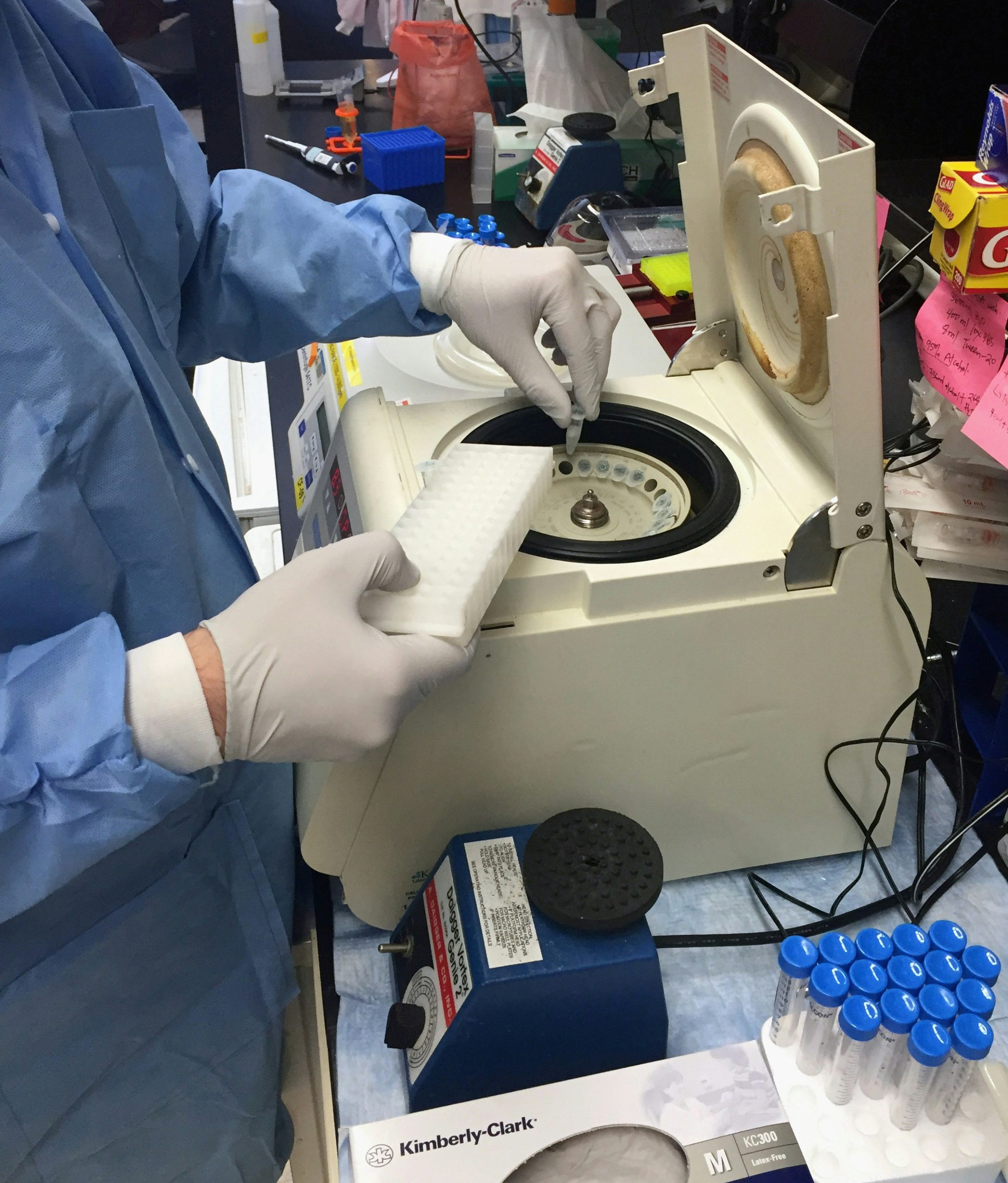

● Microcentrifuges: Ideal for small-scale laboratory work, these are used for spinning small volumes of biological samples.

● High-Speed Centrifuges: As the name suggests, these centrifuges are capable of high rotational speeds, making them suitable for more complex tasks such as the separation of fine particles.

● Ultracentrifuges: Used for extremely high speeds, ultracentrifuges can separate the smallest of particles, playing a crucial role in molecular biology research.

● Refrigerated Centrifuges: These centrifuges come with temperature control, essential for samples that require a specific temperature during separation.

Each type of centrifuge, while based on the same basic principle of centrifugation, offers unique features to suit different applications. This diversity not only showcases the versatility of centrifuges but also underlines their indispensability in various scientific fields.

Inside the Centrifuge: Key Components Unveiled

Understanding the components of a centrifuge is key to appreciating its functionality and versatility. The primary parts include:

● Rotor: The heart of the centrifuge, the rotor holds the tubes where samples are placed. Different rotor types accommodate various sample sizes and separation requirements.

● Motor: Powers the rotor, enabling it to spin at high speeds necessary for effective separation.

● Lid or Cover: Ensures safety by preventing access to the spinning rotor.

● Temperature Control System: Present in some centrifuges, it maintains the desired temperature during operation, crucial for temperature-sensitive samples.

● Speed Control: Allows the user to set and adjust the centrifuge’s rotational speed, tailoring it to specific needs.

These components work in unison, each playing a pivotal role in the centrifuge’s operation. This intricate cooperation underscores the centrifuge’s significance in various scientific and industrial applications.

The Art of Separation: How Centrifuges Work Their Magic

The magic of a centrifuge lies in its ability to separate components through rotational force. This process begins as the centrifuge’s rotor spins at high speeds, creating a force that pushes heavier particles outward. In a mixture, this means that denser substances are flung to the outer edges, while lighter substances remain closer to the centre.

The efficiency of separation depends on several factors: the speed of rotation, the size and density of the particles, and the duration of the spin. By manipulating these variables, a centrifuge can be fine-tuned to separate a wide range of substances, from blood components in medical laboratories to sediments in geological studies.

This principle of rotational separation is not just a cornerstone of centrifuge operation but also a testament to its versatility in various scientific applications.

Learn more about our centrifuges and their capabilities in rotational separation.

Centrifuges in Action: Vital Roles Across Industries

The versatility of centrifuges spans across various fields, underlining their importance in numerous applications:

● Medical Laboratories: Used for blood separation, centrifuges are crucial in diagnostics and research.

● Pharmaceuticals: In drug development and manufacturing, centrifuges play a role in purifying compounds and separating active ingredients.

● Environmental Science: Centrifuges assist in water and soil analysis, helping in the study of environmental contaminants.

● Food Industry: They are used for clarifying liquids and separating solids from liquids in food processing.

● Industrial Manufacturing: Centrifuges aid in the processing of chemicals, fuels, and other materials.

Each of these applications demonstrates the centrifuge’s critical role in advancing scientific and industrial pursuits.

Keeping the Spin Safe and Efficient: Maintenance and Safety Guidelines

Proper maintenance and adherence to safety guidelines are paramount in ensuring the longevity and effective operation of centrifuges:

● Regular Cleaning: Routine cleaning prevents contamination and extends the life of the centrifuge.

● Inspection of Components: Regular checks of the rotor, lid, and other parts for signs of wear or damage.

● Balancing Samples: Always balance the samples in the rotor to prevent damage due to uneven loads.

● Training: Ensure that all users are trained in proper operation and safety procedures.

● Servicing: Regular professional servicing to maintain optimal performance and safety standards.

By following these maintenance and safety protocols, the lifespan of centrifuges can be significantly extended, ensuring their continuous role in various critical processes.

The Future Is Spinning: Upcoming Trends in Centrifuge Technology

The future of centrifuge technology is marked by exciting advancements and innovative trends:

● Automation and Digital Integration: Modern centrifuges are increasingly incorporating automated features and digital controls for precision and ease of use.

● Miniaturisation: The development of smaller, more portable centrifuges is expanding their use outside traditional laboratory settings.

● Energy Efficiency: New models are focusing on reducing energy consumption while maintaining high performance.

● Advanced Materials: The use of stronger, more durable materials to enhance the longevity and safety of centrifuges.

These trends not only signify the technological evolution of centrifuges but also their growing importance in a wide array of scientific and industrial applications.

Conclusion: Centrifuges: Pioneering Advances in Science and Industry

In conclusion, the journey through the world of centrifuges reveals their indispensable role in modern science and industry. From their basic operating principles to the vast array of applications, centrifuges are more than just machines; they are key enablers of progress across various fields. As we have seen, ongoing advancements in centrifuge technology promise even greater efficiency and versatility in the future. Understanding the mechanics and applications of centrifuges is essential for anyone involved in scientific research, industrial processes, or any field where precise separation is crucial.

Explore the innovative world of centrifuges at Fluid BioSolutions, where we are committed to providing cutting-edge solutions for all your centrifugal needs.

For more information on our customised solutions and centrifuges, talk to our friendly team, by visiting our contact page.

Optimized by: Digital Six